HEBI Research Applications

HEBI Partners Accelerating the Future of Robotics

The HEBI Robotics platform is used by companies and universities worldwide to advance research efforts, create systems that have real-world impact, and educate the next generation of roboticists.

Our platform enables researchers and industry partners to do in days what takes months with traditional hardware. Rather than reinventing the wheel, they are freed up to concentrate on the creative and enterprising aspects of building a robot—the activities that drive their work forward and transform our world. This is what we mean by accelerating the future of robotics.

Click images below for examples of how customers have applied our technology.

Facebook is using HEBI’s hexapod Daisy to power their AI research. The tech giant chose Daisy for her stability; she is learning how to walk on her own via a machine-learning technique called self-supervised learning.

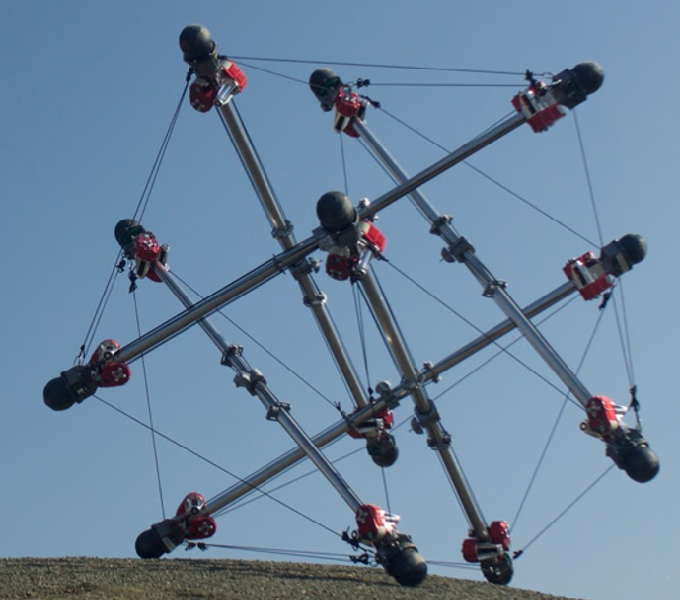

NASA Ames Research Center and UC San Diego used HEBI modules to build SUPERball V2, a tensegrity robot optimized for resilience, durability, and mobility during high-impact exploration.

California Institute of Technology students use HEBI’s platform to learn the basics of robotic systems at the intersection of computer vision, machine learning, and control. Pictured: a student group’s final project focusing on motion control and autonomy.

Carnegie Mellon University's Biorobotics Lab is using HEBI’s platform to advance their motion control research. This robotic arm mounted to a supporting backpack enables wearers to complete jobs that would otherwise require multiple people.

University of Washington's Personal Robotics Lab is using HEBI’s platform to develop new methods for robotic manipulation. Humans can teleoperate this custom HEBI robotics arm to teach it to use chopsticks and pick up challenging items.

Carnegie Mellon University uses HEBI’s easy-to-learn, cross-platform tools to teach robot kinematics and dynamics. Students learn fundamental techniques with a robotic arm and build on this foundation as the course progresses.

Cloudminds enlisted Igor, HEBI’s 14-DoF, self-balancing robotic kit, to test and demonstrate their advancements in cloud-based control of robotics.

Ericsson brought HEBI’s hexapod Daisy to Mobile World Congress to showcase robot control over 5G and illustrate the role latency plays in ensuring precise control and operation in manufacturing. Daisy danced like she was at a disco, thanks to the low latencies 5G brings.

The Robotarium @ GeorgiaTech - a state of the art remotely-accessible robotics laboratory - is using Rosie with an upgraded 7-DoF double shoulder arm to rescue broken robots from the test arena in its experiments execution pipeline.

Ericsson 5G Smart worked with HEBI Robotics to design a custom mecanum base chassis to demonstrate and evaluate 5G technologies and architecture capabilities for smart manufacturing use cases. Visit 5gsmart.eu